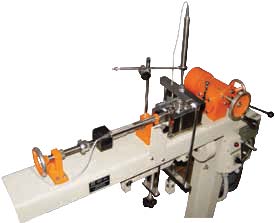

Electronic Direct Shear Apparatus, 12 Speed, Motorised with Microprocessor based Touch Panel electronic unit

The unit is same as HS 24.15 except that the transducers like displacement sensors and load cell with micro-processor based touch panel display system are provided instead of dial gauges and proving rings. Total loading capacity of the apparatus is 8 kg/cm2. It is provided with standard 60mm shear box assembly.

Set of weights to give a normal stress up to 3 kg/cm2 on the specimen through lever is provided as standard. Additional weights are to be ordered separately. Electronic Data Acquisition System For Direct Shear Test Equipment The three-channel micro controller based signal conditioning and touch panel display unit is suitable to measure Horizontal load, Horizontal Displacement and Vertical displacement directly indicated in their respective engineering units during Direct Shear Testing. The system receives the output signal from the sensors i.e. Load cell and Displacement Sensors attached to the Direct shear Test apparatus. The data of all three channels of Direct Shear Test can be transferred to computer through RS-232/ Ethernet and can be online monitored The Unit also provides the facility of online monitoring of data of all the sensors on Touch Panel Display provided at the front.

Broadly the following facilities are incorporated in the system:-

• Touch panel is provided to perform various operations such as TARE, PROGRAMMING, START, STOP etc.

• Independent Taring of each channel

• Data transfer interval is programmable (between 1 second to 1 hour)

• Automatic data saving on stop button.

• There are 25 set results having a maximum of 200 data points per set can be stored in the electronic unit .The sample number can be programmed.

• Online date and time of test will be stored along with the data.

• On line (while the test is in progress) data transfer to the computer through RS-232/ Ethernet.

Sensors Specification:-

1. Load Cell :

• Capacity : 200kg/ 2000N

• Resolution : 0.1kg/ 1N

2. LINEAR VARIABLE DIFFERENTIAL TRANSFORM ER (LVDT) 2 No.

• Stroke : ± 20mm

• Resolution : 0.01mm Software Specification

1. Data Acquisition from Signal Conditioning Unit to Computer

2. Off-Line Data Analysis Software that does all the calculations of Direct Shear Test.

3. Has option for manual as well as automatic recording of data.

4. Calculates Area, Volume, Bulk density, Dry density, Moisture content etc. of the specimen S-31

5. Display the following Plots (Graphical)

(a) Horizontal Displacement vs Shear Force

(b) Horizontal Displacement vs Vertical Displacement

(c) Normal stress vs Shear Force

(d) Maximum value of the Dilation Angle The software is windows based and user friendly.It is easy to operate and has the flexibility to enterdifferent sizes of test specimen up to 1000mm X 1000mm

Note: Computer does not form part of the supply.